BOD Reduction – Activated Sludge Process

The activated sludge (AS) biological treatment process is the most common process for reducing five-day biochemical oxygen demand (BOD5) in wastewater, for both industrial and municipal applications. Activated sludge consists of many naturally occurring aerobic microorganisms mostly in the form of bacteria, protozoa, and fungi (biomass).

The biomass uses the BOD5 in wastewater as their food source. As with any living organism, they require a very controlled environment including adequate food source (BOD5), proper nutrients (nitrogen and phosphorus), and adequate oxygen (aerobic organisms) to survive and replenish.

The AS process converts the organic waste materials to simpler compounds such as carbon dioxide, nitrates, sulfates, and more biomass. These substrates are removed from the water by either settling, DAF, or membrane separation.

The biomass reproduces to the point that some must be removed from the process. The excess biomass is referred to as waste activated sludge (WAS) and the removal process is referred to as “wasting”.

System Description

There are a number of activated sludge configurations but all function based on the same principals. All activated sludge systems incorporate an aeration basin or tank and some means of separating the biomass from the treated water phase. The primary difference in the following processes is the way that the biomass is separated from the water phase.

Continuous Flow Activated Sludge (CFAS)

The CFAS system consists of an aeration basin and solids (biomass) settler. Wastewater enters the aeration basin where it is aerated and mixed with an appropriate amount of biomass for good BOD5 removal. From the aeration basin, the mixture of biomass and treated wastewater flows to a gravity settler (clarifier). The clarifier is designed to allow settling of the biomass and discharge of the clarified wastewater. A measured amount of the settled biomass is returned to the aeration basin to maintain the correct ratio of biomass to incoming BOD5 for good treatment. The biomass that is returned is referred to as returned activated sludge (RAS). The excess biomass (WAS) is “wasted” to the solids handling system.

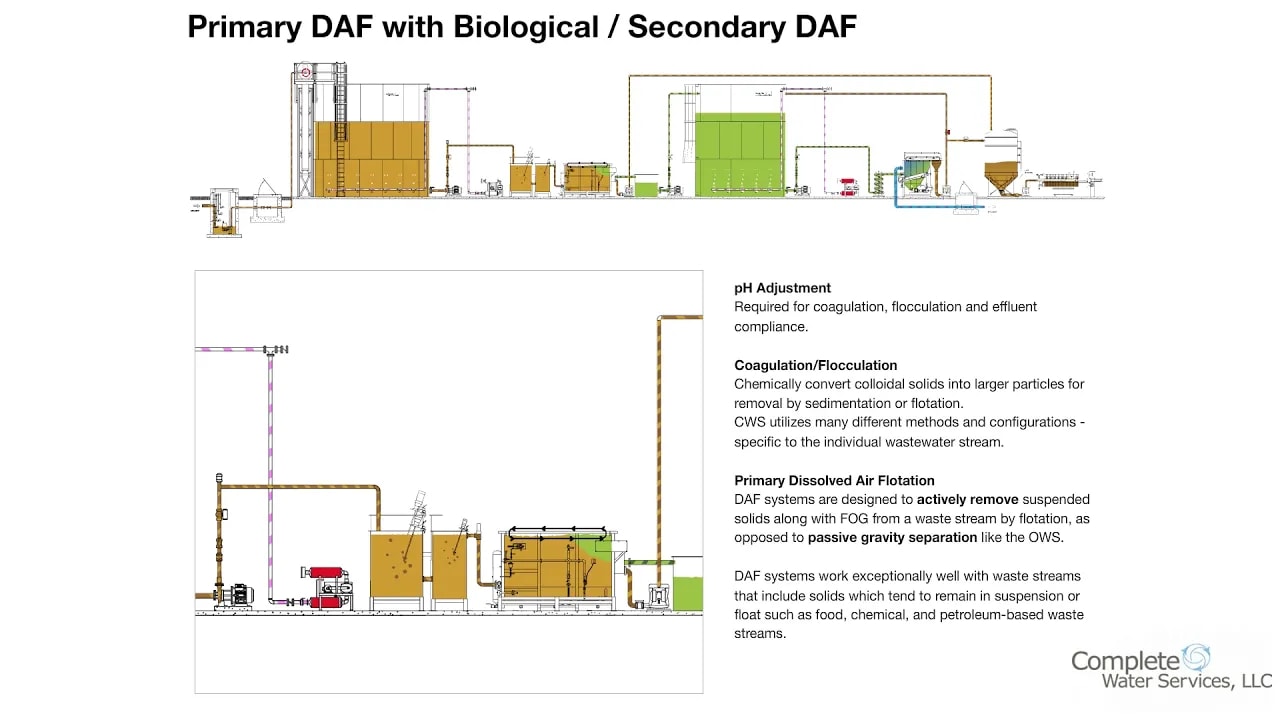

Activated Sludge Using DAF Clarification

This type system consists of an aeration basin and dissolved air flotation for solids clarification. As with the CFAS system, wastewater enters the aeration basin where it is aerated and mixed. From the aeration basin the mixture of biomass and treated wastewater flows to a DAF for clarification. The DAF is designed to promote separation of the biomass by flotation rather than settling. This type system is much more efficient and occupies a smaller footprint. A measured amount of the float (RAS) is returned to the aeration basin for treating the incoming wastewater. The excess biomass (WAS) is “wasted” to the solids handling system.

Sequencing Batch Reactor (SBR):

The SBR process consists of aeration basins only. The biomass is settled in the aeration basin by turning off the aerators creating a settling cycle within the aeration basin. Most SBR systems use two bio-reactors that operate on an alternating and sequential basis (i.e. while one basin is in the aeration mode, the second is in a settling mode). Single tank SBR systems generally use equalization to store untreated wastewater while the bioreactor is in the settling mode. Since the biomass remains in the basin, there is no RAS in an SBR system. The excess biomass (WAS) is simply removed at the end of the settling cycle.

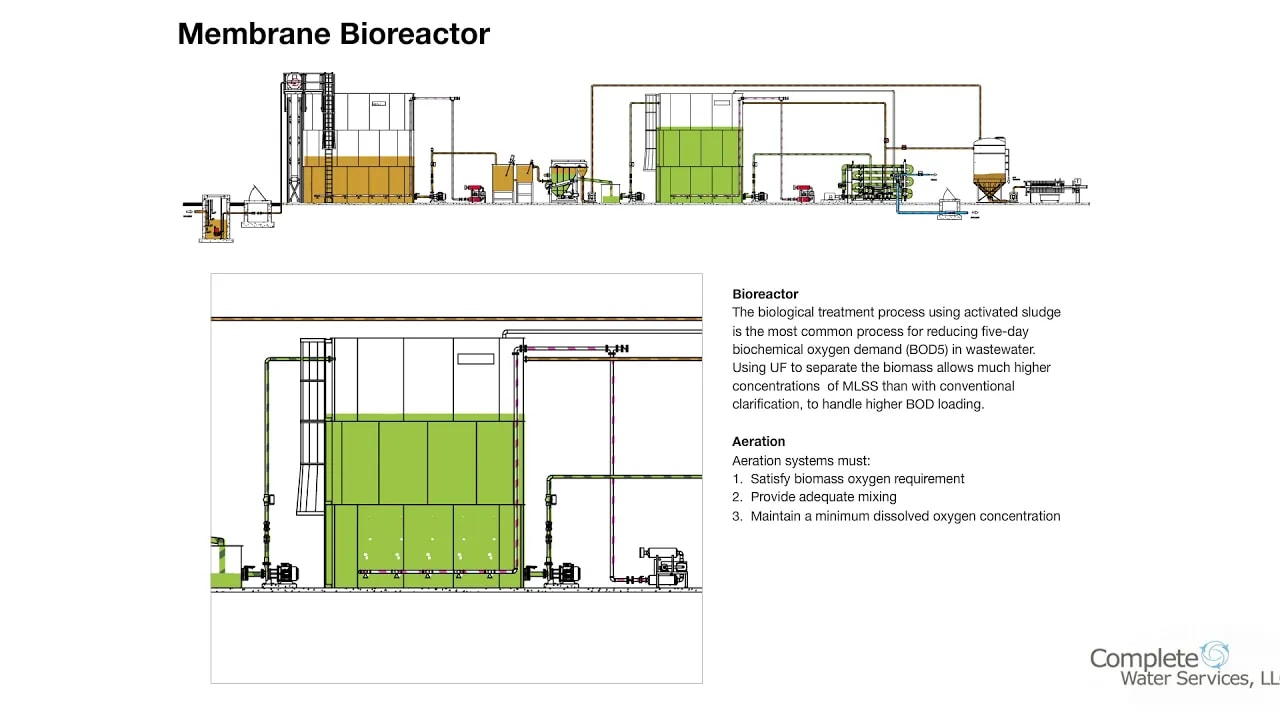

Membrane Bioreactor (MBR):

The MBR is the most advanced technology with respect to biological wastewater treatment. The MBR uses ultra-filtration membranes for separating the biomass from the treated wastewater. Due to the size of the membrane sieve virtually all of the suspended solids are removed. A well designed and operated MBR System can achieve wastewater reuse standards for municipal applications and provide significant opportunities for industrial wastewater recycling.