Design/Build Project Description

Hager Companies – Montgomery, AL

Background

Headquartered in St. Louis, Hager Companies is one of the largest manufacturers of residential and commercial door hardware in the world. The metal finishing, metal plating, and painting operations yield wastewater containing cyanide and high metals concentration. To keep pace with increased manufacturing operations, the existing WWTP at their Montgomery manufacturing facility needed to be completely replaced with a green field installation, in order to increase both capacity and reliability.

Project Requirements

- Double the capacity of existing system to 316,800 gpd

- Reuse as much of existing equipment as possible

- Design/Build system included a new stand-alone building

- Improve stability, efficiency, ease/cost of operation, and maintenance

- Continuously treat a wide range of contaminants, including cyanide

- Increase capability to treat surges of contaminant volume and concentration

- Demolish and dispose of existing WWTP (hazardous materials considerations)

- Aggressive schedule; existing WWTP equipment was in very poor condition and was subject to catastrophic failure.

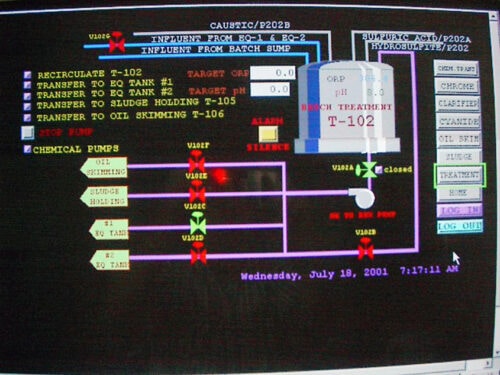

- PLC/Computer control system with graphics

- Tight budget.

System Components

- Flow equalization

- Continuous pH neutralization

- Continuous cyanide destruction

- Chemical flocculation/coagulation

- Clarification

- Cartridge filtration

- Ion exchange

- Sludge decant and filter press de-watering

- Oil separation from alkaline degreaser

- PLC/computer control with extensive automation

Results

- Design Maximized Use of Existing Equipment

- Brought On-Line With No Interruption of Manufacturing

- Green field installation including building, utilities and equipment

- Demolition/ disposal of existing system