Industrial Wastewater

Wastewater generated by industry runs the gamut from those termed as “hazardous” and “toxic” to those termed as “conventional pollutants”. Wastewater characteristics vary considerably from one industry to another and oftentimes vary greatly among plants within the same industry. In addition, significant variations in flow and contaminant levels occur hourly within the same plant.

Add into the mix that industrial facilities must meet locally developed limits and in some cases federally imposed “categorical” limits. These limits may be administered by the local governing authority (LGA), the state environmental protection department, or the federal Environmental Protection Agency (EPA), depending on who has been delegated this authority.

These factors make managing industrial discharges a very complex and challenging venture for the industrial facility. Complete Water Services and our staff have been assisting industrial facilities with the management of their water resources for many years. The following section includes some basic information regarding selected industries including process descriptions, wastewater generation and treatment alternatives.

Food Processing, Packaging, and Preparation

The food service industry covers a broad range of manufacturing processes including bread and sweet-good bakeries; meat, fish and poultry processors; vegetable preparation; animal and vegetable oil processing; beverage and condiment preparation.

Wastewater Generation

Although the manufacturing processes may be very different across the food service industry, the wastewater generated has similar characteristics and similar problems including:

- pH excursions caused by acid and caustic cleaning processes and the use or manufacturing of acidic products such as vinegar (acetic acid) and citric acid.

- High levels of settleable solids and suspended solids caused by cleaning operations and in-product loss during production.

- High levels of five-day biochemical oxygen demand (BOD5) and chemical oxygen demand (COD). BOD5 is a 5-day bio-assay type test and can be considered a measure of biodegradability as it relates to wastewater treatment. COD is a chemical degradation test that takes a few hours to complete and is used as a surrogate to BOD5.

- Excessive fats, oils and grease (FOG) caused during bakery operations, fryer and cooker cleaning; product loss during transfer; and in blending and cleanup operations. It should be noted that each pound of FOG generates approximately 2 pounds of BOD5.

Treatment System Components

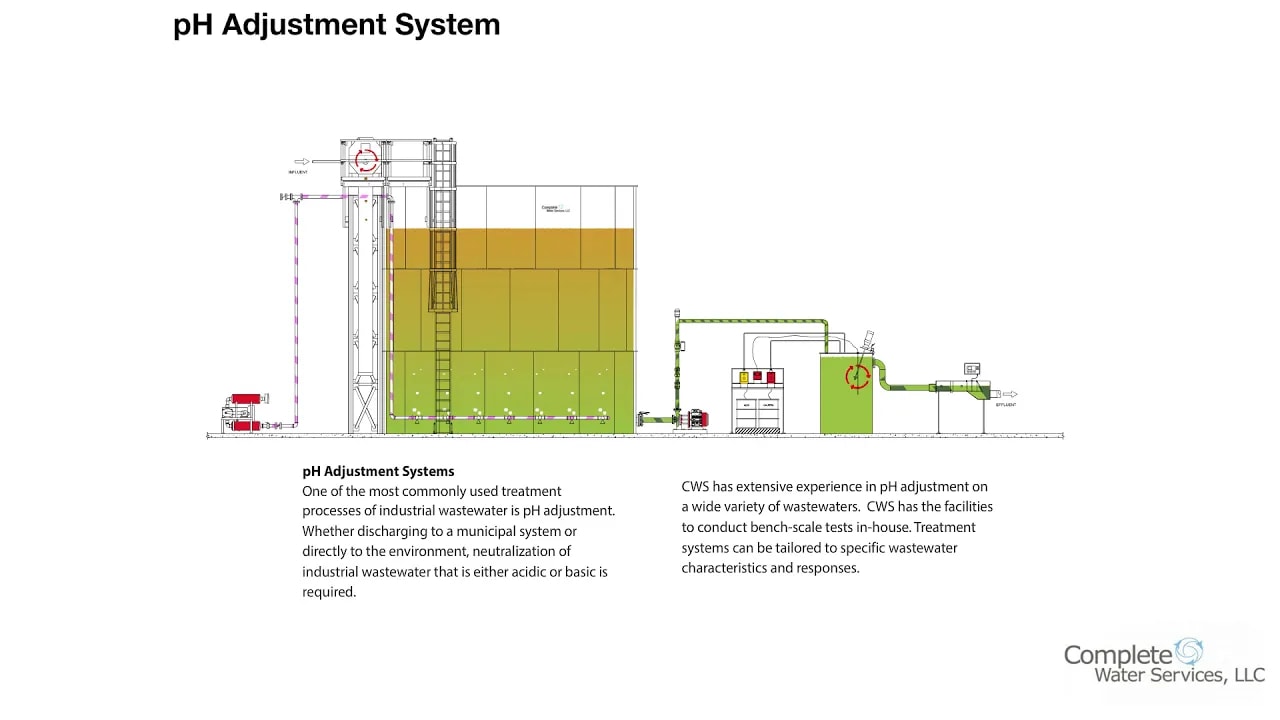

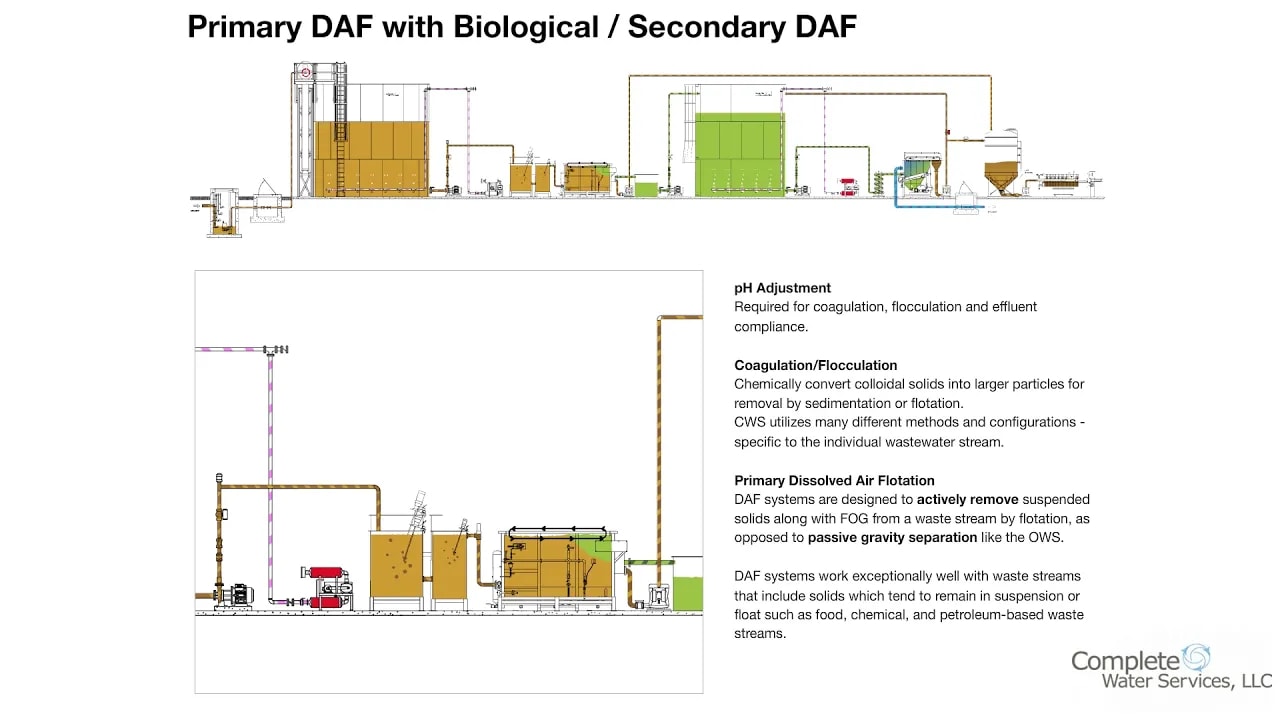

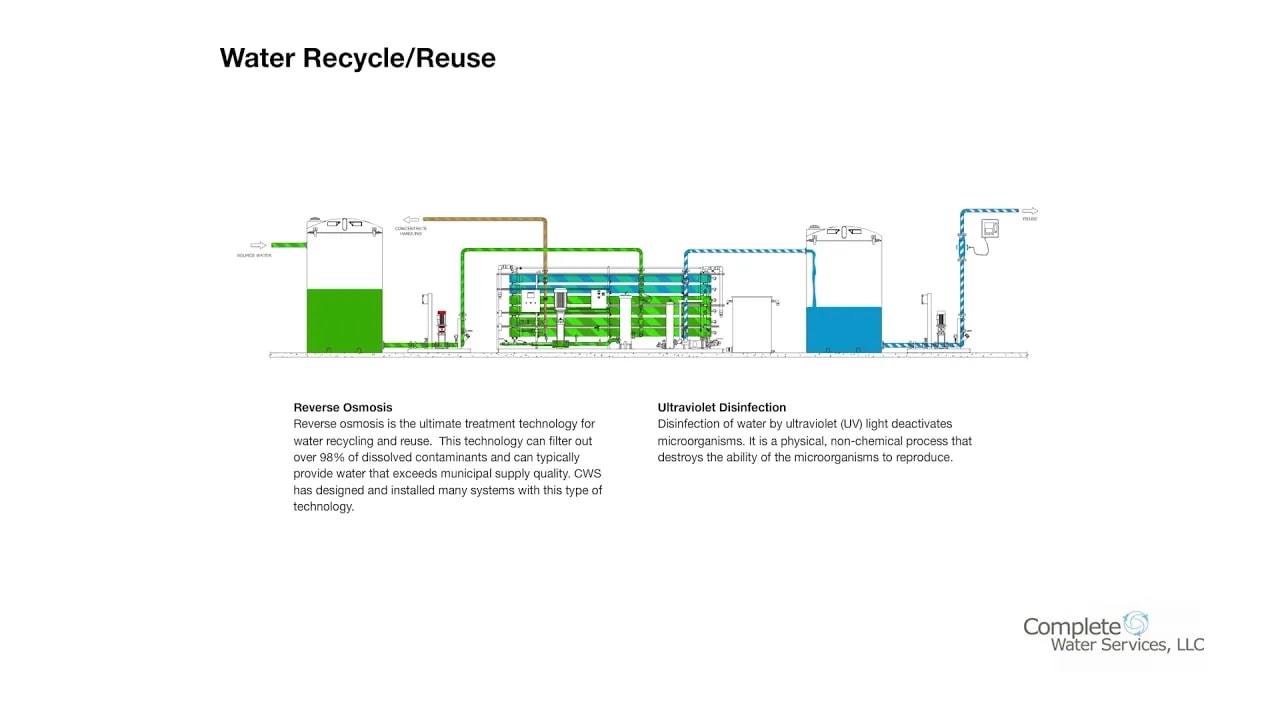

The most common treatment processes for the specialty chemicals industry:

CWS is capable of providing the following services related to your water and wastewater handling needs:

Metal Manufacturing and Metal Finishing

The metal finishing industry covers a broad range of processes including electroplating, electroless plating, anodizing, coatings, etching and chemical milling, and printed circuit board manufacturing. This is the largest group of industries regulated by USEPA Federal Categorical Standards. WASTEWATER GENERATION Although the metal finishing processes vary across the industry, the wastewater generated has similar characteristics and similar problems. Wastewater is generated from a variety of unit process including:

Wastewater Generation

Although the metal finishing processes vary across the industry, the wastewater generated has similar characteristics and similar problems. Wastewater is generated from a variety of unit process including:

- Machining

- Cleaning and surface preparation

- Acid cleaning and surface preparation

- Caustic cleaning and surface preparation

- Paint stripping

- Solvent degreasing

- Plating and coating

- Anodizing

- Etching and chemical milling

Wastewater characteristics include:

- pH excursions caused by acid and caustic cleaning and plating bath carryover.

- High levels of heavy metals used in plating operations.

- High levels of phosphorus resulting from phosphate coating operations.

- High levels of cyanide which are used to improve the plating process.

- High levels of total toxic organics (TTO) TTO List associated with oily wastewater and solvents used for cleaning.

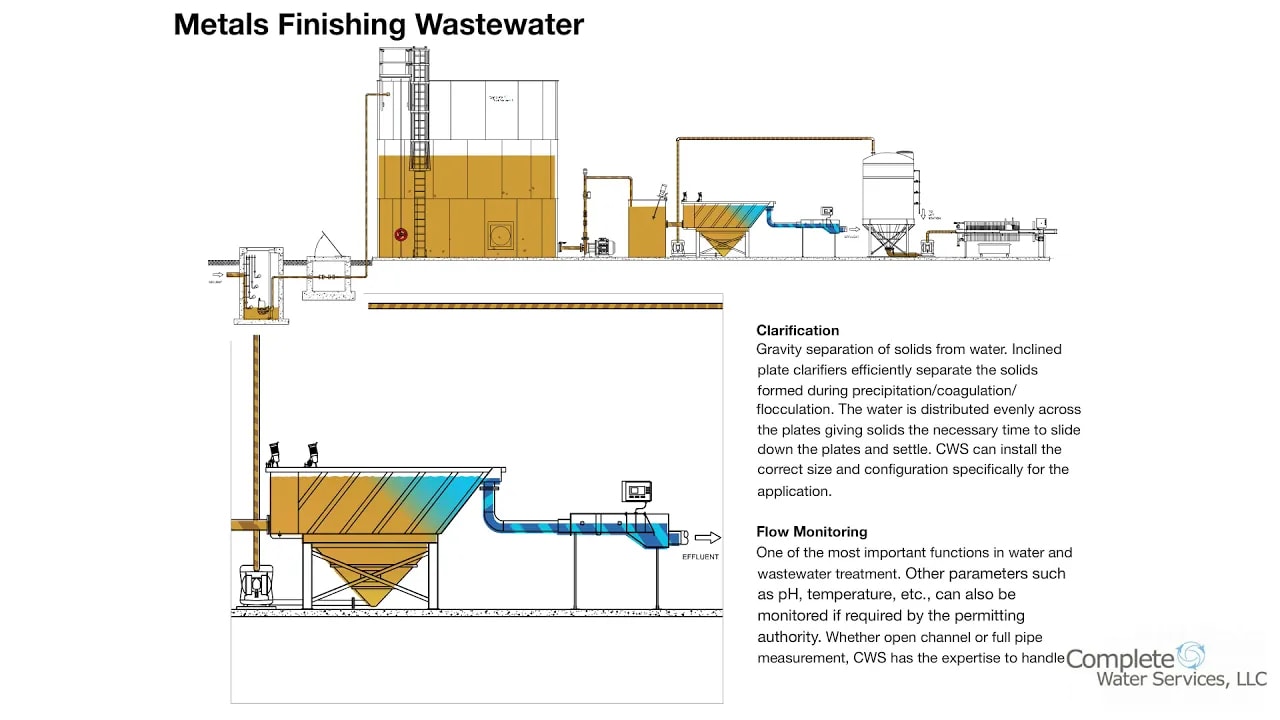

Treatment System Components

The most common treatment processes for the specialty chemicals industry:

CWS is capable of providing the following services related to your water and wastewater handling needs:

Specialty Chemical Manufacturing

Specialty chemical manufacturing covers a variety of manufacturing processes including but not limited to adhesives and sealants, coatings, carbon black, explosives, fatty acids, polymers, glycerin, printing inks, repellents, and cleaning solutions.

Wastewater Generation

The characteristic of wastewater generated from specialty chemical manufacturing varies greatly depending on the type chemical being manufactured. Primarily wastewater is generated as a result of process tank cleaning, housekeeping, and product loss. Wastewater is generally high in biochemical oxygen demand (BOD5), chemical oxygen demand (COD) and total suspended solids (TSS).

Some specialty chemical manufacturers are also regulated under the USEPA Federal Categorical Standards for Organic Chemicals, Plastics, and Synthetic Fibers (OCPSF) category and must meet a variety of limits for parameters associated with their particular category.

Other parameters of concern include:

- pH excursions

- High levels

- metals

- phosphorus

- nitrogen

- oils and grease

Treatment System Components

The most common treatment processes for the specialty chemicals industry:

CWS is capable of providing the following services related to your water and wastewater handling needs:

Textiles, Foams, and Rubber

Textile manufacturing is the weaving of cloth from either natural or synthetic fibers.

Wastewater Generation Characteristics

Treatment System Components