Control of Hydrogen Sulfide Generation

With expectations of continued growth in southern Douglas County, Georgia, the Douglasville-Douglas County Water and Sewer Authority (WSA) installed a force main from their new St. Andrews Pump Station to the existing South Central Pump station. This area of the county was seeing major growth in 2007; therefore, the new 16-inch diameter concrete-lined metal force main pipe was anticipated to initially carry 20,000 gallons of wastewater per minute a total distance of 10.8 miles. In time, this flow was expected to increase with the construction of subdivisions in the area and the tie-in of two existing schools.

Because of the initial low flow and the long distance (hence a long retention time of approximately 30 days in the pipe), WSA was concerned about the generation of hydrogen sulfide gas in the force main and Microbial Induced Corrosion (MIC).

Sanitary Pipe Corrosion

Sanitary wastes contain a variety of organic and sulfur compounds. The sulfur cycle that occurs within the wastewater as it flows down the sewer pipe is fairly well understood. Sulfates [SO42-] are reduced by naturally occurring sulfur reducing bacteria, in the absence of oxygen, to hydrogen sulfide [H2S(aq)]. The H2S(aq) migrates into the air space as a gas [H2S(g)] where it is oxidized by sulfur oxidizing bacteria into sulfuric acid [H2SO4].

The sulfuric acid produced by the bacteria attacks concrete and metal pipes. Depending on individual conditions, this attack may be swift or may occur over a period of years.

Factors Influencing Sulfide Generation

The rate of sulfide generation in a sewer system depends on the following:

- Concentrations of nutrients and organic material in the sewage: The rate of sulfide generation is proportional to the biochemical oxygen demand (BOD5) if excess sulfate is available. If excess sulfate is available, but BOD5 is low, the rate of sulfide production will be limited due to the scarcity of organic matter.

- Sulfate may be a limiting factor at concentrations below 20 mg/L.

- If the dissolved oxygen concentration is above 1.0 mg/L, sulfate reduction will be eliminated.

- The pH of the wastewater.

- The rate of biological activity of sulfate reducing bacteria doubles with every 10° C [50° F] increase in temperature.

- Retention time of the sewage within the collection system: As retention time increases, the oxygen consumption increases, thus favoring the activity of sulfate reducing bacteria.

Evaluation of Options

With new sewer installations, there are a variety of options available for reducing corrosion. These can include linings and anti-microbial concrete piping. With existing installations, options can be limited. Coatings and slip lining can be viable options if conditions warrant; however, the traditional method is regular or continuous dosing of chemicals to break the sulfur cycle by changing one of the factors stated above. This can be done by oxidation, reduction, pH control or precipitation.

Treatability Studies

Three separate treatability studies on the specific wastewater samples were conducted by engineering affiliate Rindt-McDuff Associates, Inc.:

- An initial sulfide stabilization and H2S generation using various chemical additives to determine the impact of the additives on sulfide concentration (changing the factors stated above)

- A second sulfide stabilization study based on the findings of the first study

- A treatability study of the impact of 30-day old sewage on the downstream biological treatment processes at the POTW

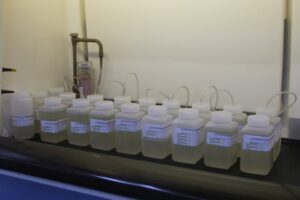

The treatability tests were conducted simulating the expected 30-day retention time of the sewage in the force main. Tests were run on each of the generation factors stated above and H2S generation was measured.

Based on the results of the treatability studies, WSA decided to pursue the traditional method of pH control of hydrogen sulfide (Factor 4) for their existing sewer system. Increasing the pH reduces the proportion of H2S(aq) in the H2S ↔ HS‾ equilibrium. At a pH of 7.0 SU, equal concentrations of dissolved H2S and HS‾ exist in equilibrium; while at a pH of 8.0 SU, only about 10 percent of the dissolved sulfide exists as H2S(aq). Increasing the pH reduces corrosion by maintaining the dissolved sulfide in the HS‾ or S‾ form. It was determined from the treatability tests that raising the pH to 10 SU at the St. Andrews pump station would maintain a pH range of 9 to 9.5 at the end of 30 days. This was found to have no adverse impact on the biological processes at a POTW.

Design and Construction of System

The installation of a pH control system for this force main was the most economical and most effective system to control hydrogen sulfide. For this site, the most effective location for the chemical addition was the existing Debris Manhole (wetwell) at the St. Andrews Pump Station.

A small heated metal building was erected at the pump station. Inside the curbed building is a 1550-gallon double-walled polypropylene tank that contains sodium hydroxide (caustic soda). A heated building was necessary due to the freezing point of 50% caustic soda. Dosing lines in secondary containment run from the building to the Debris Manhole.

Existing pumps in this wetwell provided the mixing. Because characteristics of domestic sewage at the lift station are fairly constant, dosing is based on water level inside the wetwell, which was fitted with an ultrasonic level transmitter, rather than pH. When the transfer pumps are running, caustic soda is dosed at the previous rise rate. When pumps are off, dosing is based on the rise rate of the water.

Conclusion

When this project began, it was anticipated that the flow would increase in subsequent years so that the installation of a pH control system would be temporary. However, due to the current economic conditions, growth in this part of Douglas County has fallen short of planned. The pH control system that was to be temporary has been in operation longer than initially anticipated and it continues to perform as designed. WSA has seen no corrosion in the force main and no adverse impacts on the POTW from the long retained sewage.

I would like to thank Keith Higgs, WSA, Robert E. Hadden, Rindt-McDuff Associates, Inc., and Karen J. Niebuhr, PE, Complete Water Services, LLC, for their assistance with this project.

Jim L. Lewis

President

N.A.C.E. Accredited Corrosion Technologist

Complete Water Services, LLC

678-355-9270

jlewis@cwaterservices.com